BRECOPLAN / CM A900

High-resistant industrial floors

The BRECOPLAN floor systems are high-resistant industrial floors, seamless, without joints which possess the high load strength. This material is all in one: all areas where water, oils, lubricants or industrial cleaning products attacks the floors are the perfect places for application of BRECOPLAN. Specially modified DFT bonding product together with the additives and mortar gives the extraordinary floor systems for garages, workshops, producing halls and warehouses.

The floor that can support anything

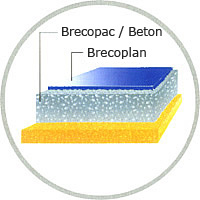

Because of its special properties, BRECOPLAN is able to support all the attacks without damages. Even after long-lasting action, BRECOPLAN keeps its high resistance. In relation to steel BRECOPLAN is completely neutral; this is very important for the all steel components which are directly in contact with BRECOPLAN. BRECOPLAN is applied over the BRECOPAC or over the existing concrete floor (B25), as well as the mezzanine flat floor slabs. BRECOPLAN is produced directly on the site and it is placed using the modern laser technology. This way, we guarantee the constant qualityt.

Could we have the seamless floor system?

Yes! The problem occurs with deviation from the level or with the holes in the floor sub-base. We apply BRECOPLAN maximum seamless even over the thousands meters square. If a horizontal movement of the concrete sub-base causes the appearance of cracks in BRECOPLAN, it could only have the visual importance but not functional. The high adhesion of the material as a result has the high cracks resistance. Especially, the surface, thanks to the bonding with the artificial resin, stays sealed and resistant, so it almost never appears separations and mechanical damages.

Comfortable, economical and does not pollute the environment.

All the successful companies know that BRECOPLAN industrial floors can support the long-term continuous use. Besides, it demands practically no maintenance. This high quality product is solvent free and surely harmless. If there is a need to wash BRECOPLAN floors, you have the specially designed product which will keep your industrial floor systems incredible for the many years.

Technical data

conditions for surface

Conditions for the sub-base: Brecopac or concrete according to DIN 1045 (min. B25)

Joints

Seamlessly in the area; expansion joints of the object must be secured by the joints profiles. It is possible to implement the specific solutions on the gates crossings and crossings between differently based construction works.

Thickness/weight

Normal thickness.......................... 1, 0 – 2,0 cm / 0,35 kN / m2

Conditions for implementation

Hall must be protected against the rain and drafts. Minimum requested temperature +5°C.

Flatness

Following the subsoil, if necessary according to DIN 18 202; tab. 3, line 3

Tensile strength

The medium value of the test-samples after 28 days, storage according to DIN 18 560, part 1.

Strength

Compressive strength............................................ > 50 N/mm2Flexural strength................................................... > 10 N/mm2

Resistance

Temperature resistance of -30°C to +80°C, high resistance to water, oils and chemicals.

Electrical conductivity

Between 104 and 107 Ohm, according to DIN 51 953, there is no static charge. Under the rules for work areas, it‘s suitable for the explosion areas zone 0, zone 10 (allowed maximum value: 108 Ohm)

Producing daily rate

800 m2 / day and team

System description

Heavy industrial floor based on the artificial dispersions. The thickness is 1, 0 – 2, 0 cm.

Properties

o seamless in the area, closed upper surface

o non-slip

o natural gray

o resistant to water, oils and chemicals

Fields of application

o garages

o producing plants

o warehouses

o workshops

o transport hubs

o high rise warehouses

o printing-works

o storage